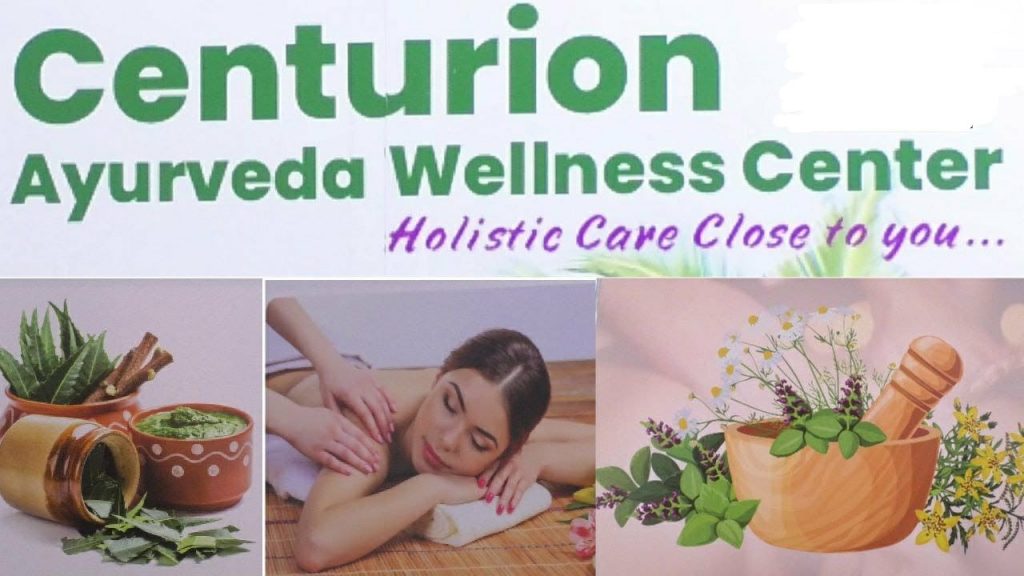

Centurion Ayurveda Wellness Centre

Genesis

“Health is wealth-” we have often heard this and unfortunately due to our busy hectic schedules we are unable to implement it in our day-to-day lives. Wellness of mind and body- both are equally important. A healthy mind in a healthy body is a sane person. To include and promote wellness among the citizens, Centurion University came up with Centurion Ayurveda Wellness Centre initially in Paralakhemundi, Odisha back in 2021. The aim was to make the services available to all. Following this, the Centre opened in Jaydev Vihar, Bhubaneswar, and in its Vizianagaram campus as well.

Aims and Objectives

The Center was started with great authenticity for the well-being of people and to bestow an excellent service to the public. Apart from guiding people to a healthy lifestyle, it also focuses on a healthy lifestyle and fullness of life. This is achieved through Ayurvedic principles that have been proven and practised for ages. The Centre treats patients based on Ayurvedic principles that have evolved through intuitive and transcendental knowledge from God. It provides quality treatments with utmost care and excellent quality patient care at affordable prices.

Products/Services Available

Centurion Ayurveda Wellness Center believes that each individual is unique, and so too are the highly customised experiences. It maintains a stock of Ayurveda medicines which are mainly sourced from standard companies with good packaging. They sell Good Manufacturing Practice (GMP) certified Ayurveda and Siddha Medicines only.

The Therapeutic Services Available at Centurion Ayurveda Wellness Center is Nādi, Pareeksha, Pratyahara, Panchakarma, Rejuvenation Therapy (Rasayana Chikitsa), Shirodhara, Elakizhi therapy, Spine therapy, SHE Clinic, Pediatric care, and Geriatric care among many others.

Benefits

Centurion Ayurveda Wellness Center is a perfect destination for a complete rejuvenation and relaxation experience. Currently set up at three locations- Visakhapatnam, Paralakhemundi, and Bhubaneswar- it is on a mission to provide good health and a better lifestyle. It is a perfect haven to undergo Ayurvedic treatment, yoga, and naturopathy treatment, attend meditation classes, and a myriad of many other services. It is a place with everything you need to relax, rejuvenate, and live a healthier, happier, and more active life.

Future goals

The objectives to be fulfilled in the near future are manifold and centred on the wellness and well-being of people. The Centre aims to bring enough awareness among people about Ayurveda for preventive health and also make it available to the general public at an affordable charge. It also plans to expand the Centre across all the campuses of Centurion University.

Adherence to SDGs

The Centurion Ayurveda Wellness Center aligns with several of the United Nations’ Sustainable Development Goals (SDGs), including SDG 3: Good Health and Well-being, SDG 4: Quality Education by providing technical training to students; and SDG 10: Reduced Inequalities. By providing affordable, high-quality Ayurvedic treatments and medicines, the centre promotes good health and well-being among the public, especially those who may not have access to traditional healthcare. Finally, by promoting Ayurveda and making it accessible to all, regardless of socioeconomic status, the centre helps to reduce inequalities in healthcare access and outcomes.